Continuously Transposed Conductors (CTCs) are transposed wire cable systems that can be used in medium and ultra-high power transformers in electrical equipment. At Sam Dong, we specialize in creating high-quality magnet wire products, specialized designs for wire applications, and providing a range of custom wire fabrication services. Since 1977, our team has been manufacturing OFHC Rods and CTCs for use in countries around the world.

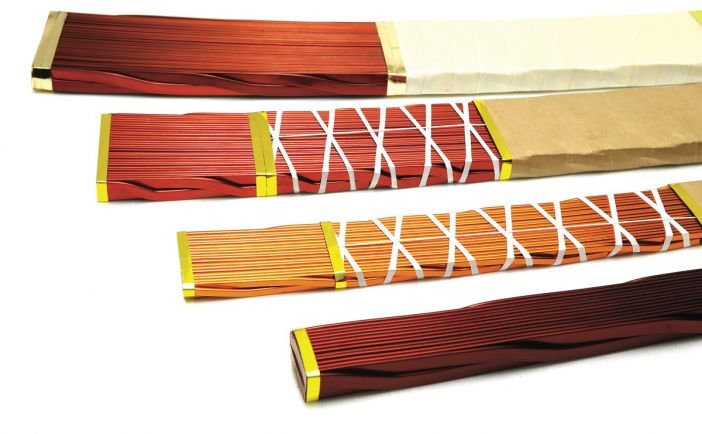

Continuously Transposed Conductors

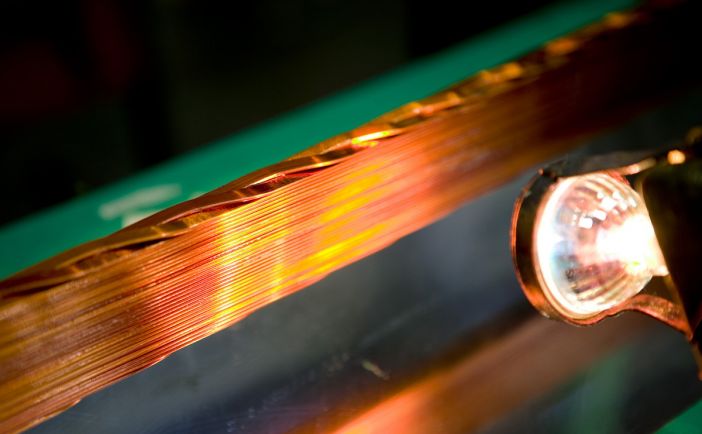

Continuously Transposed Conductors are enameled ropes of rectangular wires. Each length is formed from numerous film-insulated or enameled rectangular wires arranged in two stacks that merge slightly in the center; the purpose of this configuration is to create as many possible wire positions within the CTC. The entire assembly is often wrapped in additional insulation, such as pure cellulose paper tape.

CTC configurations come in different lengths to best suit the diameter of transformer windings for different applications and they may also contain between five and 73 wire strands. The finished product is used in power transformers as winding wires.

At Sam Dong, we construct our continuously transposed conductors from Oxygen-Free High Conductivity (OFHC) copper. Our additional options for CTC types include:

- Polyester-roped CTCs, which offers better cooling efficiency and reduces both the production cost and oil pocket

- Hardened-type CTCs, including CPR1, CPR2, and CPR3:BS1432

- Self-bonding CTCs that offer increased mechanical and electrical strength

Some of the advantages of using CTCs over other winding options include:

- Cost-effectiveness. CTCs can be used with small, less-expensive transformers to reduce the overall cost of the system. The thin insulation helps reduce the space demand for the windings.

- Ease of use. CTCs have improved winding capabilities. They are also simple for operators and machinery to handle.

- Reduce electrical loss. CTCs reduce the electrical losses that transformers suffer. They offer faster winding for shortened winding times. CTC windings also help reduce eddy current losses at the end of the winding.

- Even distribution of heat. Electrical equipment often generates high levels of heat that may damage surrounding components or diminish overall performance. The insulation and spacing improvements that CTCs offer ensures that this heat is evenly distributed across the winding.

- Improved mechanical strength. CTCs—especially self-bonding CTC types—offer better mechanical strength than alternative materials.

We’re committed to creating high-quality CTCs and other magnet wire products. We have been winning awards since 1991 due to our excellent deliveries, services, and focus on innovation, including the 2009 Siemens Supplier of the Year. We’re proud to serve multiple sectors, including:

- Aerospace

- Automotive

- Consumer goods and electronics

- Energy

- Green energy

- Industrial

- Medical equipment

- Military and defense

- Telecommunications

- Transmission and distribution centers

Contact Sam Dong Today to Place Your C.T.C Order

Every order starts with a commitment to serving your unique needs and creating the right wiring products for your equipment. We’re proud to serve businesses around the world, including Asia, North America, Europe, South America, Europe, and Oceania. Contact us today to learn about our OFHC and CTC capabilities.